Corrosion of any metal equipment is a natural phenomenon. Corrosion happens when a metal structure contacts the environment where these metal’s properties are prone to degrading due to electrochemical and mechanical processes

Materials, especially metals are susceptible to Corrosion. Your business needs to avoid Corrosion to increase the lifespan of its metallic structures such as bridges, pipelines, vessels, tanks, and so on.

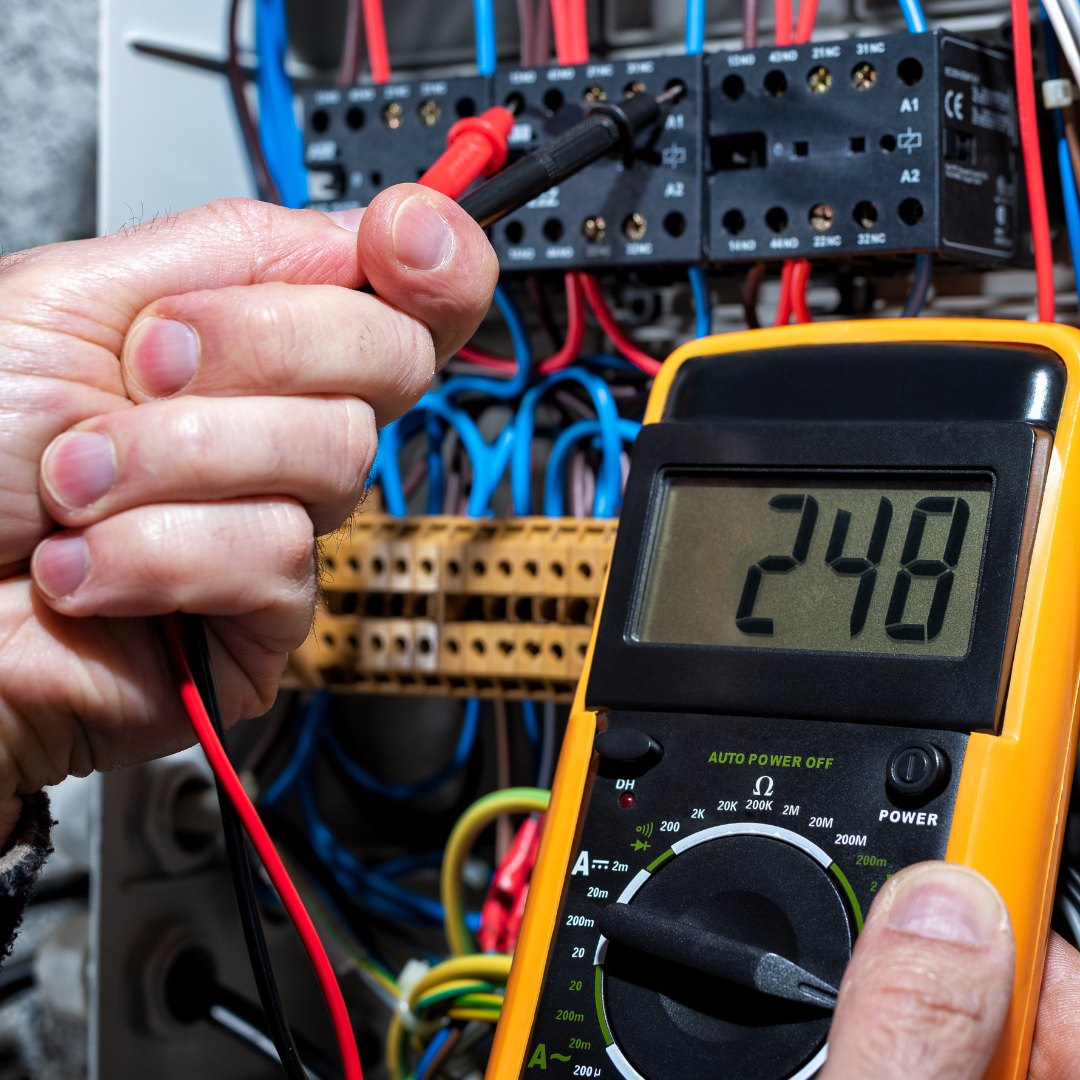

The nature of the environment and metal surface determine the rate of Corrosion. Corrosion-resistant materials are heavily used to protect troublesome areas such as pipelines, pumps, valves, meters, and pump columns. Cathodic Protection is the electrical solution to the Corrosion problem found in structures such as marine, storage tanks, underground vessels, well casings, harbors, subsea equipment, and pipelines.

It is all about forcing the metal to be negative or more Cathodic than its natural state. With the help of Cathodic Protection technology, you can have a protective layer to protect your precious metallic structure from significant material loss. Here, one material is intentionally used to protect another.

Field Of Applications

- Energy Pipelines Petroleum Oil and Gas, Well Casings, Underground Steel Structures

- Marine structures

- Submerge strutures

- Pipeline structures

- Metal reinforced concrete structures

- Water systems

- Metal reinforced concrete structures

- Underground structures

The sheer ignorance of Corrosion prevention can steal the strength of the structure despite industry and your business vertical, turning the metal equipment structure into junk. Various methodologies and techniques are available to prevent Corrosion and are embraced by businesses that deal with metallurgic and engineering applications. The perks of employing Cathodic Protection technology for your business are:

- Corrosion wearing process can be suppressed

- Retains the metallic structure for a longer period of time

- No more Corrosion material loss

- High safety

- Higher Safety and Integrity

How we stand out from the competition

Our veteran engineers are pioneers in Cathodic Protection technology and deliver comprehensive services including procurement, construction, and maintenance programs. We look for weak spots and apply our strong engineering and safety background to get a real-life understanding of the Corrosion design of the structure. Full-fledged Corrosion service is assured with us.

- Technically competent team

- Sharp focus on Corrosion science and technology

- Well-trained engineering workforce

- Veteran knowledge in Corrosion fundamentals and management

- Estimate the current requirement with accuracy

- NACE qualified Cathodic Protection engineers

- On-time delivery of products and services

- In-house manufacturing capacity

- Skilled in upstream and downstream facilities

- Internationally recognized standards